Why Every Manufacturing Business Needs Power BI for Scalable Growth

- What is Power BI and Why It Matters for Manufacturing Industry?

- What Makes Power BI Essential for Manufacturing Businesses?

- How Power BI Helps Manufacturing Businesses Scale

- How to Implement Power BI in Your Manufacturing Operations

- Common Challenges Manufacturers can Solve with Power BI

- How to Use Power BI Dashboards to Drive Decisions

- Real-Life Success Stories

- Future of Manufacturing with Power BI

- Conclusion

In today’s fast-paced global market, manufacturing businesses are under immense pressure to optimize processes, reduce waste, and improve profitability. Manual reporting and siloed data can no longer provide the agility needed to compete. This is where business intelligence for manufacturing becomes a critical asset.

By leveraging Power BI for manufacturing operations, companies worldwide can transform complex production data into actionable insights, enabling faster, smarter decisions and unlocking unprecedented growth.

What is Power BI and Why It Matters for Manufacturing Industry?

Power BI is Microsoft business intelligence solution designed to help organizations visualize, analyze, and share insights from their data. For manufacturers, consolidating data from ERP, CRM, production lines, and supply chains into interactive dashboards is revolutionary.

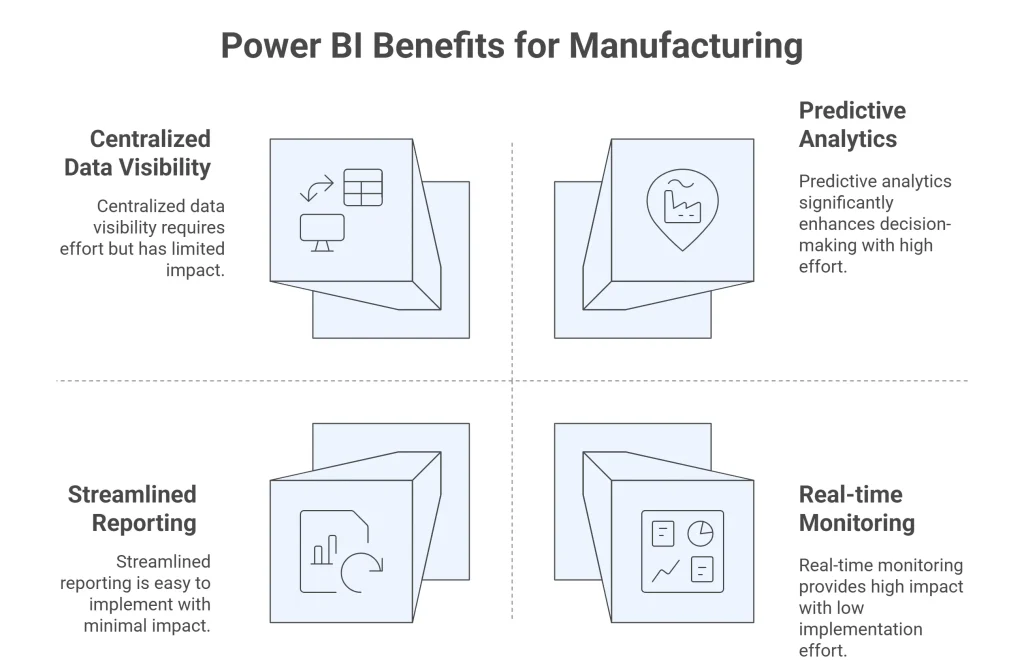

What Makes Power BI Essential for Manufacturing Businesses?

- Centralized data visibility for all departments

- Real-time monitoring of production and performance

- Enhanced decision-making with predictive analytics

- Streamlined reporting that reduces manual effort

By adopting manufacturing analytics with Power BI, companies can identify bottlenecks, track KPIs, and forecast production trends with unprecedented accuracy.

How Power BI Helps Manufacturing Businesses Scale

Power BI is more than a reporting tool—it’s a growth enabler. Here’s how:

1. Real-Time Production Analytics

To track production performance in manufacturing using data Power BI connects it directly to machines, IoT sensors, and ERP systems to deliver real-time insights into key metrics, allowing managers to make immediate adjustments and optimize production output.

2. Cost Reduction and Supply Chain Optimization

One of the biggest challenges for global manufacturers is excessive operational costs. By analyzing data on energy consumption, material usage, and labour productivity, Power BI for manufacturing cost reduction can help identify hidden inefficiencies. Furthermore, Power BI dashboards for supply chain tracking enable businesses to monitor supplier performance, inventory levels, and logistics delays, ensuring timely delivery and improving customer satisfaction.

3. Predictive Maintenance and Smart Factory Operations

Looking to the future, predictive maintenance with Power BI is transforming factory floor management. By analyzing data from machines and sensors, Power BI can forecast potential equipment failures, allowing for proactive maintenance and minimizing costly unplanned downtime.

According to a report by Deloitte, “Manufacturers that invest in advanced analytics are 5x more likely to improve operational efficiency and decision-making across global operations.”

How to Implement Power BI in Your Manufacturing Operations

Implementing Power BI doesn’t have to be complex. Follow these steps to get started:

- Identify Key Data Sources: ERP, MES, CRM, IoT sensors, and financial systems

- Define KPIs: Production efficiency, defect rates, supply chain performance

- Integrate Data: Use Power BI connectors to unify multiple datasets

- Build Dashboards: Create interactive dashboards for managers, engineers, and executives

- Set Alerts & Reports: Automate notifications for critical metrics

By following this process, you can learn how to implement Power BI in manufacturing operations and start seeing measurable results quickly.

Common Challenges Manufacturers can Solve with Power BI

- Siloed Data: Power BI integrates data from multiple sources, providing a single source of truth.

- Delayed Decision-Making: Real-time dashboards enable faster responses to production issues.

- Manual Reporting: Automation reduces errors and frees up staff for higher-value tasks.

- Limited Forecasting: Predictive analytics help anticipate demand, supply, and maintenance needs.

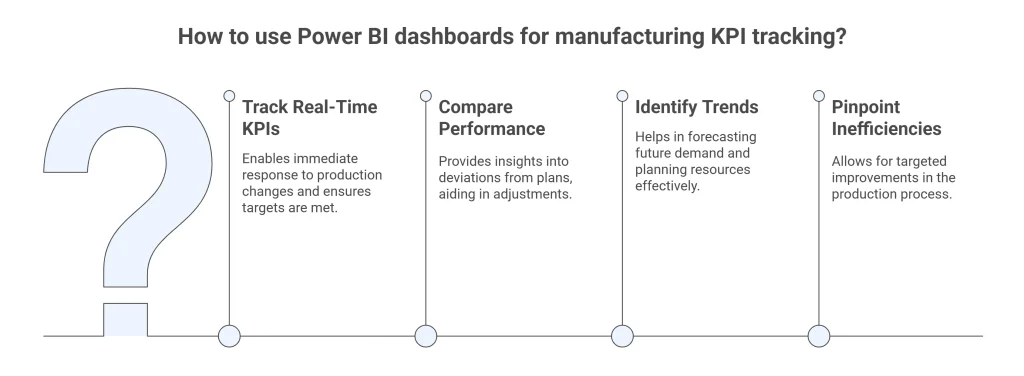

How to Use Power BI Dashboards to Drive Decisions

Dashboards in Power BI are visual storytelling tools for your data. Manufacturers can:

- Track real-time production KPIs

- Compare actual vs. planned performance

- Identify trends and forecast demand

- Pinpoint inefficiencies in the production process

Learning how to use Power BI dashboards for manufacturing KPI tracking allows managers to make informed, data-driven decisions that improve operational efficiency and profitability.

Real-Life Success Stories

- Case Study 1: A European automotive manufacturer integrated Power BI across its factories, resulting in a 15% increase in production efficiency within six months.

- Case Study 2: A global electronics manufacturer reduced supply chain disruptions by 20% after implementing Power BI dashboards for inventory and supplier management.

These examples illustrate how business intelligence solutions for manufacturing are transforming industries worldwide.

You can also read our detailed case study on streamlining project management with Power BI, where a manufacturing company transformed operations with real-time insights and 30+ interactive reports.

Future of Manufacturing with Power BI

The future of manufacturing is digital. With Power BI, organizations can leverage:

- Predictive maintenance using IoT data

- AI-driven quality inspections

- Smart factories with automated decision-making

By adopting these technologies, manufacturers can stay competitive in a global market and continue to scale their manufacturing business using Power BI effectively.

Conclusion

At Codevision, we believe that leveraging data is the foundation for sustainable growth in manufacturing. Power BI for manufacturing business growth equips organizations with real-time insights, optimized processes, and confident decision-making.

By partnering with us, you can transform your data into your most powerful growth asset. Let us help you scale your manufacturing business with a robust business intelligence solution

Frequently Asked Questions

Power BI enhances scalability by:

- Providing centralized data visibility across departments.

- Enabling real-time production monitoring.

- Facilitating predictive analytics for proactive decision-making.

- Streamlining reporting processes to reduce manual effort.

Yes, Power BI seamlessly integrates with a wide range of systems, including ERP, CRM, and IoT platforms, ensuring a unified view of your manufacturing operations.

Implementing Power BI involves:

- Assessing your current data infrastructure.

- Identifying key performance indicators (KPIs) relevant to your operations.

- Integrating data sources into Power BI.

- Developing customized dashboards for different departments.

- Training staff to utilize the platform effectively.

Codevision Technologies specializes in delivering tailored Power BI solutions for manufacturing businesses. Our team ensures seamless integration, customized dashboard development, and comprehensive training to empower your organization with data-driven insights.

Power BI vs Tableau vs Looker: Choosing the Right BI Tool for Your Business