Transforming HSEQ Through Lean Six Sigma for Operational Excellence using Microsoft Technologies

In the modern industrial landscape, where operational quality, safety, and environmental sustainability define organizational success, Health, Safety, Environment, and Quality (HSEQ) management emerges as a critical pillar. However, ensuring compliance, minimizing risks, and achieving operational excellence presents complex challenges.

This is where Lean Six Sigma comes into play—a proven methodology that integrates Lean’s waste elimination principles with Six Sigma’s data-driven defect reduction techniques. Together, they provide a comprehensive framework to optimize processes, enhance decision-making, and drive measurable improvements, making them indispensable for effective HSEQ management.

This article delves into how Lean Six Sigma principles can be leveraged to elevate HSEQ processes, delivering impactful outcomes in safety, compliance, and operational efficiency.

Applying Lean and Six Sigma Principles to HSEQ Management

1. Lean Principles:

Lean focuses on identifying and eliminating waste within processes, ensuring optimal resource utilization and efficiency. In the context of HSEQ, this translates to:

- Streamlining Safety Protocols.

- Simplifying Compliance Workflows.

- Reducing Delays in Incident Reporting or Regulatory Updates.

2. Six Sigma Methodology:

Six Sigma employs a systematic, data-driven approach to identify and reduce process variability and defects. Its application in HSEQ ensures:

- Consistent Compliance with Safety & Environmental Regulations.

- Enhanced Accuracy in Monitoring Critical Performance Indicators.

- Minimization of Risks & Incidents caused by Process Inefficiencies.

Key Ways Lean Six Sigma Elevates HSEQ

1. Enhanced Safety Performance

Lean Six Sigma methodologies focus on identifying bottlenecks and inefficiencies in safety operations, such as redundant reporting mechanisms, slow response times, and outdated protocols. By streamlining these processes, organizations can:

- Mitigate Risks Proactively.

- Reduce Workplace Accidents.

- Cultivate a Robust Safety-first Culture.

2. Optimized Compliance Management

Six Sigma’s data analysis capabilities empower organizations to uncover patterns of non-compliance. This enables the creation of predictive models and preventive measures that ensure:

- Adherence to Stringent HSEQ Regulations.

- Avoidance of Regulatory Penalties & Reputational Risks.

3. Streamlined Environmental Processes

Lean methodologies excel in identifying areas of resource waste and environmental inefficiency. Applied to HSEQ, this results in:

- Optimized Resource Utilization to Reduce Waste.

- Improved Energy Efficiency and Reduced Carbon Emissions.

- Enhanced Alignment with Sustainability Objectives.

4. Data-Driven Decision Making

Lean Six Sigma integrates statistical tools like DMAIC (Define, Measure, Analyze, Improve, Control), enabling organizations to make informed decisions based on actionable insights. This ensures:

- Proactive Identification of Potential Risks.

- Accurate Monitoring of Safety & Quality Metrics.

- Continuous Improvement driven by Real-Time Data

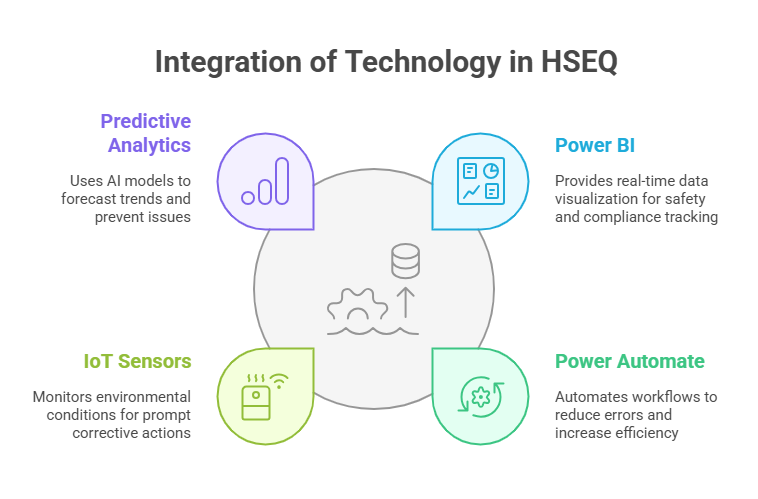

Technical Tools to Augment Lean Six Sigma in HSEQ

To fully leverage Lean Six Sigma principles in HSEQ, organizations can integrate advanced technological tools for real-time monitoring, process automation, and predictive analysis:

-

Power BI:

Provides interactive dashboards and data visualization to track safety trends, compliance metrics, and operational KPIs in real time.

-

Power Automate:

Automates critical workflows, including incident reporting, audit trails, and compliance tracking, reducing manual errors and increasing process efficiency.

-

IoT Sensors:

Enables continuous environmental monitoring, detecting anomalies in air quality, temperature, or hazardous emissions, ensuring prompt corrective action.

-

Predictive Analytics:

Leverages AI-driven models to forecast safety risks and non-compliance events, enabling preemptive measures.

Transforming HSEQ with Lean Six Sigma

Lean Six Sigma fosters a culture of continuous improvement and operational excellence in HSEQ by blending technical methodologies with innovative technologies. Organizations that adopt this framework can achieve:

- Improved safety performance through streamlined processes.

- Regulatory compliance with data-driven insights.

- Sustainability by reducing environmental waste.

- Operational efficiency through automation and predictive analytics.

Partner with Codevision for Your HSEQ Transformation

At Codevision Technologies, we specialize in enabling organizations to elevate their HSEQ processes through cutting-edge solutions powered by Lean Six Sigma principles and Microsoft’s M365 ecosystem. From advanced analytics with Power BI to automated workflows via Power Automate, we deliver tailored solutions that align with your unique operational goals.

Contact us at sales@thecodevision.com to explore how we can drive your HSEQ transformation and unlock unparalleled operational excellence.

Modern Regulatory Reporting in Financial Services with Microsoft Power BI